Surface Processing Custom Engineered

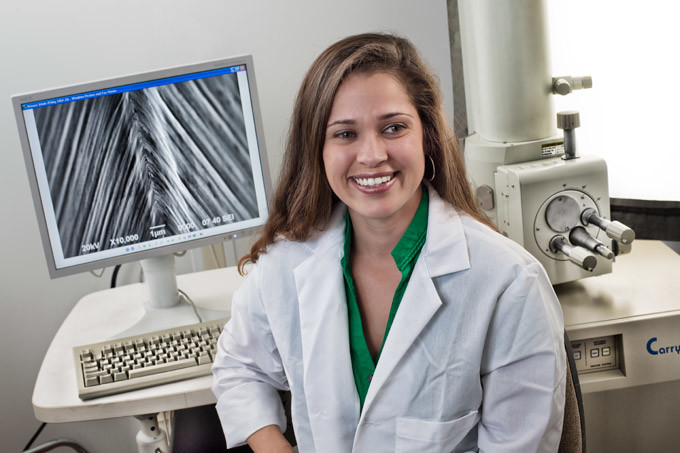

AccuTec brings mechanical, physical, and process engineering expertise to every detail of blade manufacturing—and edge coatings are the important finishing touch. Very thin surface coatings increase wear resistance and reduce friction at the tip.

Rust-resistance. Strength. Durability.

Our industry partners—whether in auto glass, fiber, plastic, film, or food processing—require a blade edge designed specifically to its application regardless of the use; however, consistent cutting quality is critical. Our extended-life corrosion-resistant coatings minimize down time, reduce waste, and boost productivity.

The coating finishes the blade.

Medical, double edge, and other specialty blades undergo a rigorous three-part process that creates a more durable cutting surface and friction-reducing lubricity. After a thorough cleaning, a hard coating is applied. To complete the process, a low-friction polymer top layer is vapor-sprayed.

For some applications, the final stages of blade processing are performed for a controlled cleanroom-compliant environment. The end result is a finely honed, sharp, and clean edge.