Quality Checks at Every Stage

Even before the metal enters the plant each shipment must be pre-certified for compliance to AccuTec’s material properties standards. But even that is not enough. A receiving test is also conducted to ensure the steel meets the necessary criteria for its intended use.

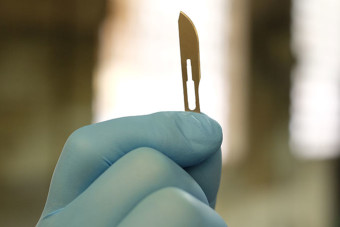

Routine and rigorous audits are conducted many times during a single blade run to ensure that all blades conform to our high performance standards. Each time a batch is about to enter production before the lines goes full speed, we conduct a “first article” inspection. Before and after metal perforation, heating, grinding, surface processing, cleaning, packaging, and shipping—all along the production line from start-up to mid-run to end of run, each blade is tested and retested.

Training Makes it Possible

Every AccuTec auditor brings a basic aptitude and background for materials testing, but hiring the right people is only the beginning. An arduous three-month in-house educational program ensures instrument proficiency. And, even after initial training, we work closely with our “Blade U” graduates to be sure they understand all dimensions of their job. Knowing that the ultimate quality of the product is “on the line”, all of us at AccuTec Blades take QA very, very seriously.

Certifications

ISO 9001 and ISO 13485

AccuTec Blades has earned ISO 9001 certification indicating the presence of a sound Quality Management System and demonstrating its focus on meeting customer expectations and delivering customer satisfaction.

AccuTec has also earned certification in ISO 13485 which signifies their Quality Management System is compliant with regulatory requirements for medical devices.

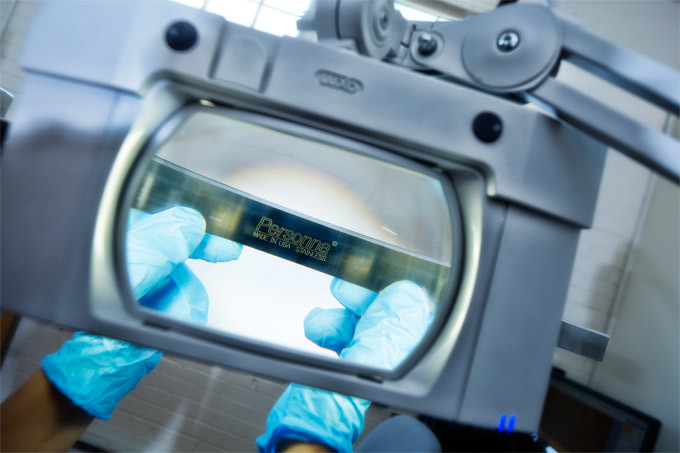

American Standards for Testing Materials International (ASTM)

ASTM chose AccuTec Blades to provide blades for testing safety gloves and related fabrics and materials. The sharpness of our blades set the international ASTM 1780 industry standard for cutting force resistance.